In today’s rapidly evolving industrial landscape, predictive maintenance is becoming a cornerstone of operational efficiency. At HMI2025 , Pepperl+Fuchs , in collaboration with Bosch Digital Twins Industries and Syntax , will unveil an innovative solution that demonstrates how seamlessly Industrial Internet of Things (IIoT) data can be integrated into established cloud platforms like AWS and MS-Azure. This groundbreaking product highlights the transformative power of digital tools in industrial environments.

Introducing the Digital Twin Starter Kit

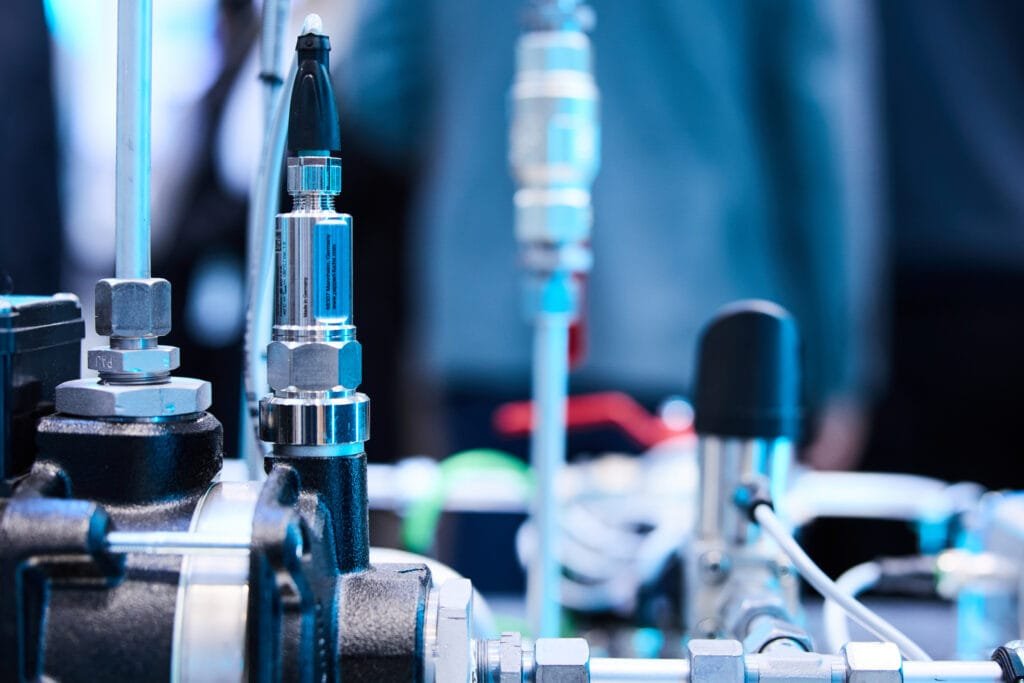

The Digital Twin Starter Kit by Pepperl+Fuchs is designed to simulate real-world applications, showcasing its potential to revolutionize predictive maintenance in industrial plants. This all-in-one package includes:

- Advanced Sensors : High-performance process sensors capable of capturing comprehensive field-level data.

- IO-Link Master : Acts as the bridge between sensors and the embedded PC, preprocessing and aggregating critical data for further analysis.

- Fanless Embedded PC : Ensures reliable performance without the risk of overheating or mechanical failure.

- Seamless Integration Tools : All components required for effortless connectivity and data transfer to cloud-based platform.

This kit simplifies the implementation of predictive maintenance solutions by providing a plug-and-play system that automatically configures itself upon connection to the internet and power supply. The use of open communication standards ensures maximum flexibility, allowing businesses to scale their operations as needed.

How It Works: Real-Time Data Analysis and AI-Driven Insights

Once the field-level data is aggregated by the IO-Link master, it is transmitted to the Bosch Digital Twin platform , also referred to as the Intelligence Core . Here, a simulation model powered by intelligent asset performance management (IAPM) performs real-time analysis of the data.

Leveraging machine learning (ML) algorithms and artificial intelligence (AI) , the system delivers actionable insights, such as:

- Failure Prediction : Early detection of potential equipment failures to prevent costly downtime.

- Maintenance Optimization : Recommendations for optimal maintenance schedules, reducing unnecessary servicing while ensuring equipment longevity.

- Actionable Recommendations : Proactive suggestions to address potential issues before they escalate, ensuring smooth plant operation.

These capabilities empower industrial plants to transition from reactive to predictive maintenance strategies, significantly enhancing operational efficiency and reducing costs.

Key Benefits of the Starter Kit

- Ease of Use : The system is designed for quick deployment, with automatic configuration upon setup, making it accessible even for businesses new to IIoT.

- Scalability : Its open platform architecture allows companies to tailor the solution to their specific needs, whether for small-scale operations or large industrial facilities.

- Cost Efficiency : By preventing unexpected breakdowns and optimizing maintenance schedules, businesses can save on repair costs and minimize production disruptions.

- Future-Proof Technology : The integration of AI, ML, and cloud platforms ensures that the solution remains relevant as technology evolves.

About Pepperl+Fuchs

With over 6,450 employees worldwide and revenues exceeding EUR 840 million in 2024 , Pepperl+Fuchs is a global leader in industrial sensor technology and explosion protection. Headquartered in Mannheim, Germany, the company combines cutting-edge research with practical innovation to deliver solutions tailored to the demands of modern automation.

Founded in 1945 as a small family business, Pepperl+Fuchs has grown into a multinational enterprise with more than 40 subsidiaries across six continents . This global presence enables the company to maintain the highest technical standards while offering cost-effective solutions for manufacturing and process automation.

As a trusted partner for industries worldwide, Pepperl+Fuchs provides a comprehensive portfolio of proven components, empowering businesses to achieve greater efficiency, reliability, and sustainability in their operations.

Why Choose the Digital Twin Starter Kit?

- Comprehensive Predictive Maintenance : Harness the power of real-time data analysis and AI-driven insights to optimize plant performance.

- Plug-and-Play Simplicity : Minimal setup time and automatic configuration ensure a seamless user experience.

- Proven Reliability : Built with robust components and tested for demanding industrial environments.

- Scalable and Flexible : Adaptable to businesses of all sizes and compatible with leading cloud platforms.

For more information about the Digital Twin Starter Kit and how it can transform your industrial operations, visit Pepperl+Fuchs’ official website and explore the future of predictive maintenance.

Image Source: google.com