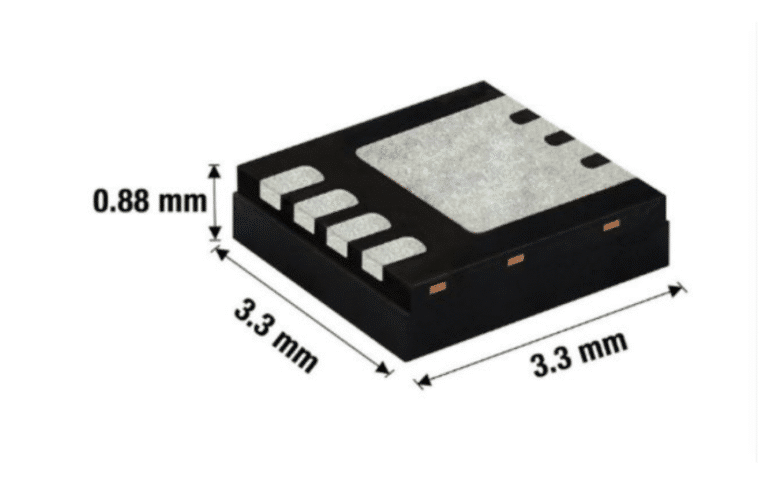

Vishay Intertechnology, Inc. has introduced a groundbreaking lineup of 27 standard and Trench MOS Barrier Schottky (TMBS) surface-mount rectifiers in the innovative DFN33A package . Designed for space-constrained applications, these devices feature a remarkably low profile of 0.88 mm and wettable flanks, enabling improved thermal performance and operational efficiency.

The DFN33A package , part of Vishay’s renowned Power DFN family, boasts a compact 3.3 mm x 3.3 mm footprint , making it 44% smaller than the SMB (DO-214AA) and 20% smaller than the eSMP series SMPA (DO-220AA) . Its ultra-thin design is 2.6x thinner than the SMB (DO-214AA) and SMC packages , and 7% thinner than the SMPA (DO-220AA) , ensuring optimal use of PCB space while maintaining exceptional thermal management capabilities.

Industry-Leading Current Ratings and Versatile Voltage Options

These rectifiers set new benchmarks in their category, with the standard devices offering current ratings up to 6 A and the TMBS devices delivering industry-best ratings up to 9 A . The portfolio includes a wide range of voltage options, spanning 60 V to 200 V for TMBS rectifiers and up to 600 V for standard rectifiers , catering to diverse application needs.

For added reliability, Automotive Grade versions are available, fully qualified to the AEC-Q101 standard , ensuring robust performance in demanding environments such as automotive systems.

Applications Tailored for Modern Power Systems

The DFN33A rectifiers are specifically designed for low-voltage, high-frequency inverters , DC/DC converters , freewheeling diodes , and polarity/rail-to-rail protection circuits . These applications are commonly found in baseband antennas, power over Ethernet (PoE) systems, switches, routers, and optical network equipment.

With a high-temperature operation capability of up to +175 °C , coupled with an exceptionally low forward voltage drop and minimal leakage current, these devices enhance design efficiency and reliability. The wettable flanks of the DFN33A package enable automatic optical inspection (AOI), eliminating the need for costly X-ray inspections.

Superior Design for Automated Assembly and Environmental Compliance

Engineered for seamless integration into modern manufacturing processes, the DFN33A rectifiers offer an MSL moisture sensitivity level of 1 , per J-STD-020 , with a maximum peak temperature of 260 °C during reflow soldering. These devices are fully RoHS-compliant , halogen-free , and feature matte tin-plated leads that meet the JESD 201 class 2 whisker test , ensuring long-term durability and environmental safety.

Why Choose Vishay’s DFN33A Rectifiers?

The combination of a compact 0.88 mm profile , wettable flanks , and superior thermal performance makes Vishay’s DFN33A rectifiers an ideal choice for engineers seeking high-efficiency power solutions in space-constrained designs. Whether you’re working on commercial, industrial, or automotive applications, these devices deliver unmatched performance and reliability.

For more information about Vishay’s DFN33A rectifiers and other innovative products, visit Vishay’s official website .

By leveraging advanced packaging technology and optimized thermal design, Vishay continues to lead the way in delivering cutting-edge solutions that address the evolving demands of modern electronics. Stay tuned for further updates on their expanding portfolio of high-performance components.

Image Source: google.com

Recipocal link: Viesearch – The Human-curated Search Engine